1. Electro-galvanized steel wire rope

The electro-galvanized steel wire rope is actually made up of fine pure zinc grains by the manufacturer after adding zinc grains for processing and refining. For the general steel wire rope in our life, the amount of zinc is 750g/m2. However, the amount of zinc on the electro-galvanized steel wire rope can reach 1200g/m2. Therefore, the amount of zinc on the electro-galvanized steel wire rope is relatively high compared to the amount of zinc on the general steel wire rope.

2. Hot-dip galvanized steel wire rope

The hot-dip galvanized steel wire rope is completely different from the electro-galvanized steel wire rope. The hot-dip galvanized steel wire rope is mainly a kind of iron-zinc compound formed by the physical reaction and the slow diffusion of heat. In layman’s terms, it is the zinc that the manufacturer processes and refines at room temperature or plated by other methods.

Hot-dip galvanized steel wire rope is a market trend and will become the first choice for users of galvanized steel wire rope. Because the hot-dip galvanized steel wire rope has a high cost performance. The steel wire of the hot-dip galvanized steel wire rope is formed by physical thermal diffusion to form a coating. First, an iron-zinc compound is formed, and then a pure zinc layer is formed on the surface of the iron-zinc compound on the surface of the galvanized steel wire. The highest value of zinc on the hot-dip galvanized steel wire rope is only 593g/m2. Hot-dip galvanizing will reduce the mechanical properties of the steel wire, requiring high-strength and high-corrosion-resistant galvanized steel wire ropes.

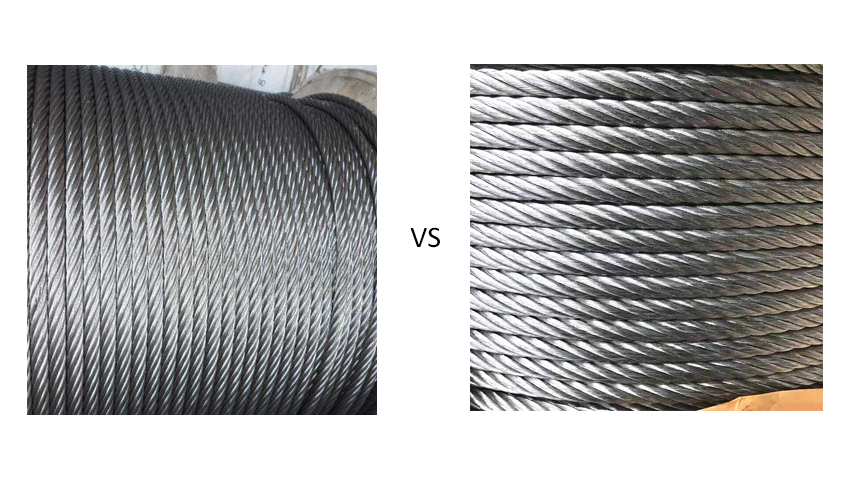

The essential difference between hot-dip galvanized steel wire rope and cold-dip galvanized steel wire rope is that the zinc layer of hot-dip galvanized steel has better corrosion resistance than cold-galvanized steel due to the zinc-iron alloy layer. The surface state of the hot-dip galvanized steel wire rope is a little black because of the hot-dip galvanized zinc-iron alloy. However, there is no chemical reaction on the electroplating surface, so it is still the natural color of zinc, which looks brighter. Under normal circumstances, the zinc layer of hot-dip galvanizing is thicker and the corrosion resistance is better. The zinc layer of electro-galvanizing is thinner and the corrosion resistance is poorer. (Unless the zinc layer of cold galvanizing also reaches the level of thick zinc layer)

The following are the concerns of our users, in the end is the galvanized steel wire rope better, or the hot-dip galvanized steel wire rope? Can’t generalize, it depends on what you use it for. For example, the supporting steel wire in the water pipe is better plated, looks good, and has a low cost; if it is a power tower, it should be hot-dip galvanized. Because of the good corrosion resistance of hot-dip galvanizing, it can be used for 30 to 40 years. Because the zinc content on the surface is high, but because the surface of the hot-dip galvanized steel wire rope has a layer of zinc-iron alloy, its anti-corrosion ability is much higher than that of the cold-dip galvanized steel wire rope. At present, the market is generally galvanized steel wire rope, because hot-dip galvanizing is expensive, the profit of dealers selling hot-dip galvanizing is low, and the appearance is good, but the anti-corrosion ability of electro-galvanized steel wire rope in the air is only one and a half years. However, the anti-corrosion ability of hot-dip galvanized steel wire rope is long. In terms of appearance, the appearance of cold galvanized steel wire rope is brighter and more beautiful, but the appearance of hot-dip galvanized steel wire rope is black.

Post time: Jul-01-2022